Interference lithography is an unique technology to fabricate highly periodic as well as stochastic surface relief structures in photoresist materials. By modification of process parameters, a large variety of different profile shapes can be generated. One- and two-dimensional structures are realized, whereas the structure geometry could be sinusoidal, parabolic, triangular or even binary. The strength of interference lithography is its upscaling potential to very large, seamless structured areas with a beautiful homogeneity (up to one square meter and even larger). After generating photoresist masters, copying processes by common replication technologies allow the highly cost-effective production of large area fi lm products as well as small structured polymer products.

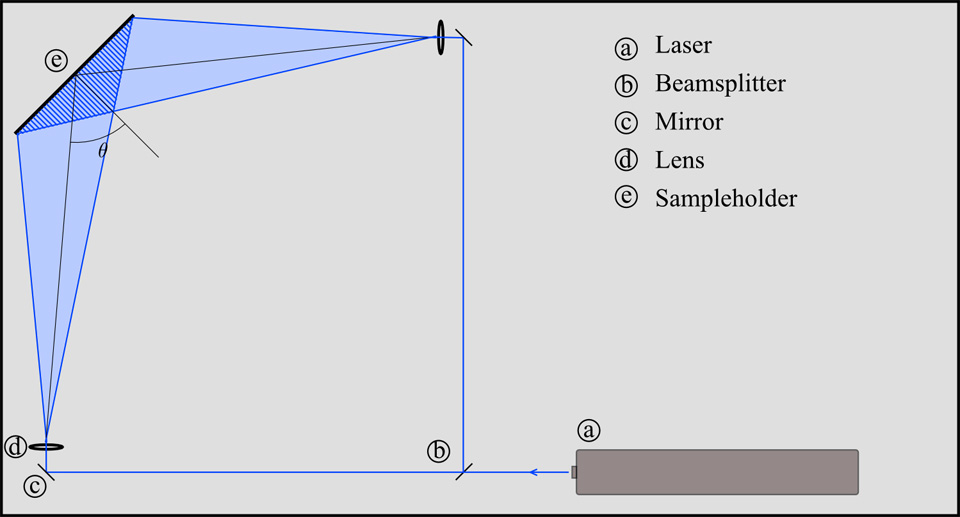

图示干涉式蚀刻法

The interference etching method is using the mirrors and the lens to bifurcate a specified wavelength beam, then widen them and cross them to form into a sinusoidal interference to do the exposure of the resist. The pattern thus exposed is of a consistent specification on a flat plane. Its cycle is decided by the angle of incidence. Nowadays, the 351nm wavelength is more commonly used. The spacing of the pattern can be less than 200nm. If more narrow is required, the resist and the light beam must be more matching.